Protective Coatings

New Vehicle Preservation Package

Designed for new, clean, or restored vehicles to prevent corrosion before it ever begins.

Corrosion Treatment and Protection

Engineered to neutralize existing corrosion and create a long term protective barrier.

New Vehicle Coatings

Designed for new, clean, or restored vehicles to prevent corrosion before it ever begins.

Rust Treatment and Correction

Engineered to neutralize existing corrosion and create a long term protective barrier.

Black Dye- Infused Exterior Trim Coating

Developed to restore, rejuvenate, and protect exterior plastic and rubber surfaces

Defend against corrosion with Aegis

IGL Aegis is a revolutionary graphene reinforced anti-corrosive clear coating system that is designed to protect surfaces in high corrosive (C5) environments. It is a 2-component (2K) paint system made from a silicone hybrid resin with the addition of graphene to improve its performance and mechanical properties. Aegis is specifically formulated to protect metals, concrete, glass, and all other kinds of surfaces from the damaging effects of corrosion, making it an essential tool for various industries such as automotive, agricultural, marine or manufacturing.

Durable

Tested for 6,000 hours- salt spray test. Tested for 4,000 hours- water immersion test.

Transparent

Detect early signs of corrosion quickly and easily.

Graphene Reinforced

Graphene nanotubes give the surface a boost in hydrophobicity.

Free From Toxic Metals

No Xylene, Lead, Isocynate, Chromium, or Zinc.

Multi Surface Use

Raw or powdercoated metals, glass, concrete, wood, plastic.

Optional Pigmentation

Aegis can be tinted any color to aid in surface imperfections

Get the most use out of your equipment without premature replacement due to corrosion. Keep your profit up, business running efficiently, and your customers happy!

Protecting Your Assets

Among one of the most impressive features of Aegis is it’s ability to be “tinted”— almost like paint. So not only can Aegis provide unparalleled protection against corrosion, it can actually aid in the appearance of failed paint! With the combination of tint and high gloss, the possibilities are endless.

Tinting Aegis

Aegis is extremely durable; as it as been tested up to 6,000 hours (salt spray) and tested up to 4,000 hours (water immersion). No other anti-corrosion coating system on the market comes close to achieving these results! When fully cured, Aegis reaches a 10H hardness. This improves resistance to impacts and abrasion such as rocks, road debris, and salt. It also improves resistance against harsh chemicals.

Enhanced Durability

Aegis exhibits self-cleaning qualities due to its highly hydrophobic nature. As a result, any dirt or contaminates that come into contact with the surface are less likely to adhere and can be easily washed away with a simple rinse.

Dirt + Water Resistance

Aegis can preserve any painted, pigmented, or powder coated component. Preserve your equipment and parts from sun fading and keep your assets looking brand new!

UV Resistant

$276 billion

U.S. companies spend on corrosion prevention, mitigation and repair per year.

2023 SEMA Global Award Winner

FAQ’s

-

Aegis is a graphene-reinforced, silicone hybrid, resin-based 2K paint solution. Created specifically to protect against highly corrosive environments (C5).

The ISO Corrosivity Classification table defines six corrosivity categories:

(C1 – very low, C2 – low, C3 – medium, C4 – high, C5 – very high, CX – extreme).

C5 = industrial areas with high exposure to pollutants, coastal and marine settings.

Traditional anti-corrosion coatings often employ the use of thick paint pigments which often cover the entire surface to prevent permeation. Unfortunately this makes it difficult to identify and locate corrosion at an early stage. This is where Aegis shines as the clear anti-corrosion coating.

-

Aegis uses Graphene Nanotubes (GNT).

GNT increases Aegis’s performance significantly. It acts as an excellent barrier against both oxidation and chemical attacks. GNT improves barrier properties making it harder for water molecules to pass through.

The benefits in GNT includes a lighter, stronger more durable coating. Weighing in at only 50 µm per layer, Aegis is significantly lighter while being stronger than traditional solutions.

As a result of this unique anti-corrosion clear coating system, signs of corrosion are detected immediately, allowing for early preventive measures. This can save time, costs, and accidents.

-

Aegis can be applied to a wide range of surfaces including metal (raw/stainless steel, aluminum, alloy, painted or powdercoated) wood, concrete, glass, rubber or any other material susceptible to corrosion, deterioration or sun fading.

-

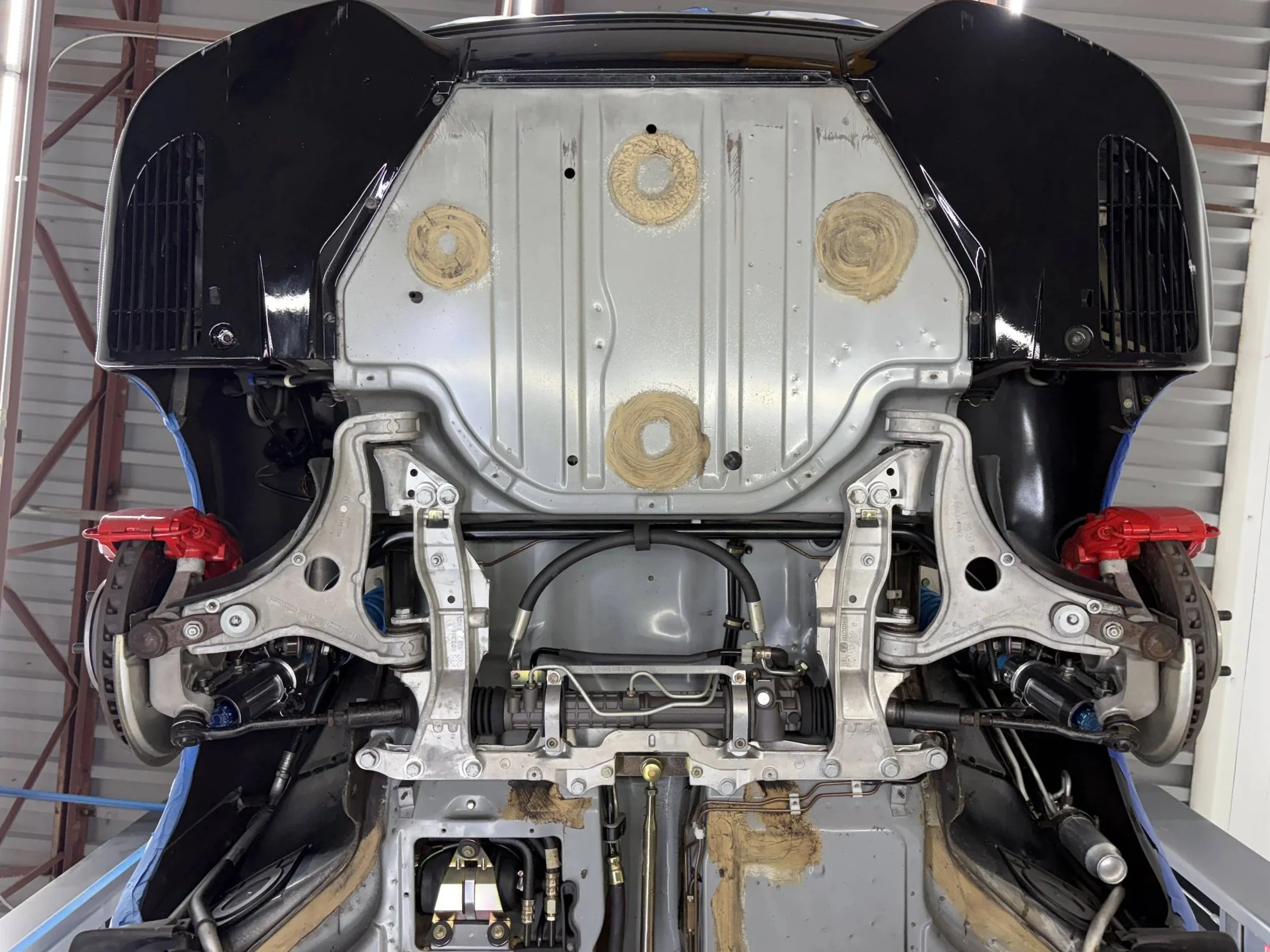

Yes! Aegis is commonly used in automotive applications to protect vehicle underbodies, frames, chassis, suspension components, and other metal parts from corrosion caused by exposure to moisture, road salt, and other environmental factors. It is also commonly used in conjunction with powdercoat to ensure a prolonged life. (i.e chipping, fading)

-

The durability of Aegis depends on various factors such as application method, environmental conditions, and surface preparation.

Aegis has been salt spray tested for up to 6,000 hours and had an outstanding result with the water immersion test, at 4,000 hours.

Aegis is proven to provide unmated protection in highly corrosive environments for years to come.

-

No maintenance is required after installation. However, regular washes are recommended to keep the surface free and clear from dirt and debris.

-

Aegis is typically dry to the touch in 6-8 hours.

After we finish coating your project, we will let it sit overnight to ensure a proper, uninterrupted cure. Once the initial curing is complete, your vehicle or equipment is ready to be put back into service.

It is important to note that the FULL chemical cure time will happen over the course of 30-60 days. Rest assured, your equipment is still safe to use without compromising the coating’s integrity.

-

No!

Nuts and bolts will still be easily installed or removed. Connectors will still plug and unplug freely. Aegis will not hinder the ability to work, service or modify your vehicle or equipment.

-

There is no comparison!

Aegis is a 2k high gloss, transparent, anti-corrosive paint system that is designed for use in extremely corrosive environments. It cures at a 10H hardness, yet is pliable and flexible to absorb impact and abrasion. It is extremely hydrophobic which helps the surface stay cleaner for a longer period of time. The high gloss and transparent finish gives the owner a peace of mind knowing that any leaks can be easily detected. Added bonus: it looks AMAZING!

A “typical undercoating” is usually oil, wax, or rubber based, black in color, sticky, goopy, and just straight up gross! It is typically reapplied once a year to protect the chassis from rust caused by salt. It is visually unappealing and will make a mess when it’s time to service. Undercoating can also hinder the ability to detect leaks or any failed components.

-

We will address any and all signs of corrosion before we start coating your project in order for the coating to adhere properly.

With approval from our client, we will scale down any existing rust using the necessary mechanical methods such as sanding, grinding, or wire brushing.

-

The cleaner, the better! However, it is not necessary to clean your part or vehicle before drop off.

We will clean and degrease your project as it is part of our standard preparation process.

With an advanced preparation process, we will utilize dry ice to clean the surface in its entirety. Dry ice cleaning will guarantee a contaminate-free surface. This would be recommended for any surface with extreme contamination that cannot be removed by hand.

-

Pricing for anti-corrosive coatings will vary drastically based upon the quantity of product required per job and the current condition of the surface.

For example, a brand new piece of equipment will cost much less to coat than a used piece of equipment because of the surface preparation required.

Our rate of service is $258/hr and material cost will vary based on the size of the project.

-

We do not offer mobile services at this time.

All work is to be performed at our location in Boynton Beach, FL.

Got a Question?